Aoheng Machinery Technology

As a leading pile driver,Aoheng has been in the pile driver manufacturing business for over 30 years. Besides railing pile driver ,we can make photovoltaic piling machine ,pile driver on truck mod,aerial work truck platform,railing cleaning truck and straightening machine,etc.

Main series four categories

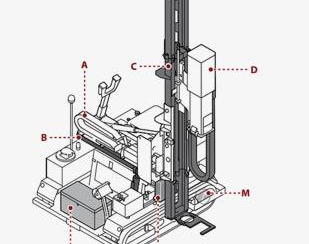

- Guardrail pile driver

- Pile driver on truck mod(railing urgent repair truck)

- Aerial truck platform

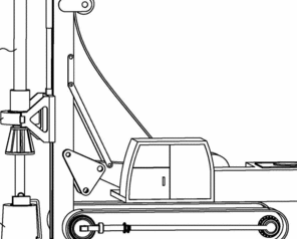

- Truck mount pile driver(install pile driving rig for user)

Category

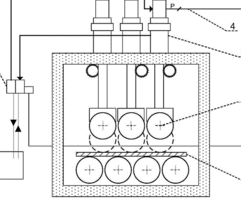

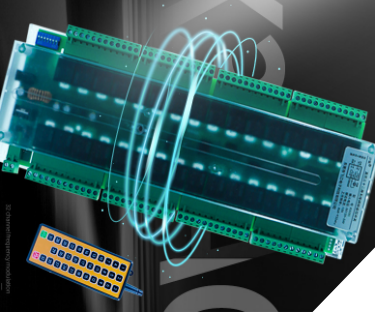

There are many types of products. Various products come in multiple levels of specifications. Can meet users with different needs. In addition to traditional conventional types, it can also be reconfigured with additional radio remote control artificial intelligence devices

Pile driver on-site scene

When you are traveling by car, you may inadvertently encounter our equipment under construction. When you stop to inquire about the performance of this equipment, the operators will all a thumbs up and say it’s very good.

Why can you trust Aoheng

Our factory’s products focus on the integration of mechanical engineering and electronic circuit control engineering. It has high automation performance and can be operated with GPS navigation and radio control, and can also be equipped with remote control devices for customers’ own equipment.

Frequently Asked Questions

We have a list of questions and relevant answers prepared for you. If your question is not answered below. you can contact us directly

We accept payment through Western Union,L/C, T/T, and D/A

Our standard products have a lead time of two weeks; special orders have a lead time of one month.

You can get a wide and accurate selection range with detailed description on the linked product pages. The special needs of customers can also be available.

(1)Suitable for harsh environmental conditions. It can be operated in safe areas, ensuring the safety of operators.

(2)No need for multiple coordination, can be completed by a single person, improving work efficiency and reducing labor costs.

Build a professional customer service team, provide high-quality logistics services, formulate reasonable return policies, strengthen communication with consumers, and provide a variety of payment methods.

Latest Article

Discover our latest news and articles regarding Aoheng machinery technology. Having deep understanding about us can help you choose the right one for your.